An introduction to industrial liquid paraffin and the differences between its grades based on flash points ranging from 100 to over 200 degrees Celsius; guidance on selecting the best type for various industries with expert advice.

What is Industrial Liquid Paraffin?

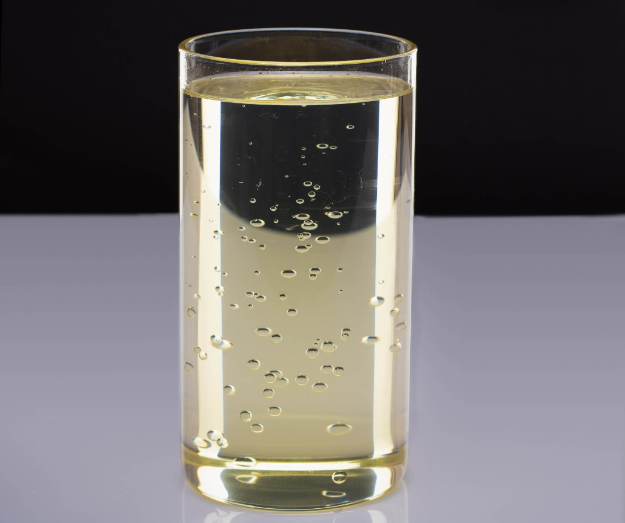

Industrial liquid paraffin is a hydrocarbon chemical compound obtained through the refining process of crude oil. This colorless or slightly yellowish, odorless substance with varying viscosities has wide applications in different

industries. One of its most important features is the flash point, which determines the safety, quality, and range of use of paraffin.

The Importance of Flash Point in Industrial Liquid Paraffin

Flash point is the temperature at which the vapors of a substance ignite when exposed to a flame or spark.

The higher the flash point, the safer and more stable the paraffin. Different industries must select the appropriate flash point grade depending on their application to maintain product quality and prevent potential hazards.

Different Grades of Industrial Liquid Paraffin Based on Flash Point

In the industry, industrial liquid paraffins are usually available with flash points ranging from 100°C to over 200°C. Each grade has specific characteristics:

- Flash 100-120°C:

Suitable for light lubrications, regular candle manufacturing, and non-sensitive uses. This type evaporates relatively faster and is recommended for low to medium temperature applications. - Flash 130-150°C:

Used in coating industries, waterproofing, and anti-rust material production. Thermal stability is better in this range compared to lower flash points, and the fire risk is reduced. - Flash 150-170°C:

Ideal for the rubber, plastic, and industrial additives industries. This grade has very low evaporation, helping improve the durability and quality of final products. - Flash 170-190°C:

Used in more sensitive industries such as cable manufacturing, industrial insulations, and some non-therapeutic medical equipment. This paraffin has very high thermal endurance and oxidation resistance. - Flash above 190 to 220°C:

This grade is for highly sensitive industries such as specialized electrical equipment, military industries, and sensitive oil and gas projects. It offers the highest levels of safety and stability.

Technical Characteristics of Industrial Liquid Paraffin

Industrial liquid paraffin generally has the following properties:

- Colorless or slightly yellowish

- Odorless or neutral odor

- Density around 0.8 to 0.9 g/cm³

- Insoluble in water but soluble in organic solvents

- Resistant to light and oxidation if stored properly

Specialized Applications of Industrial Liquid Paraffin

- Rubber and Plastic Production:

Industrial paraffin increases flexibility, softness, and prevents cracking of rubber products. It also acts as a lubricant in plastic manufacturing processes. - Textile Industry:

Used in finishing processes to waterproof and improve fiber quality. - Paints, Resins, and Protective Coatings:

Adding paraffin increases stability, moisture resistance, and improves anti-rust properties. - Candle Manufacturing and Lubricants:

Used in the production of industrial candles and manufacturing of industrial lubricants. - Special Pharmaceutical and Cosmetic Uses (in refined grades):

Highly purified industrial liquid paraffin is used in creams, lotions, and medicinal ointments (these grades must meet pharmaceutical standards).

Important Points When Purchasing Industrial Liquid Paraffin

- Choosing the Right Flash Point:

Always select the flash point suitable for your process temperature and industrial needs. - Checking Purity:

In sensitive industries like pharmaceuticals or electrical, using high-purity paraffin is essential. - Storage Conditions:

Liquid paraffin should be stored in sealed containers, away from sunlight, and at cool temperatures to prevent property changes. - Safety Precautions:

Use protective equipment such as gloves, safety glasses, and ensure proper ventilation when handling paraffin.

Summary

Selecting the appropriate grade of industrial liquid paraffin based on flash point is a key factor in the quality and safety of final products. Different industries should choose the paraffin with a flash point suited to their processes.

Petroil Trading, with extensive experience in supplying industrial paraffins, is ready to meet your needs with the best quality and expert consultancy services.