Colored solid paraffin is a type of paraffin with a variety of colors and high quality, widely used in candle making, decorative, cosmetic, and hygienic industries. In this article, get familiar with the features, production method, and

applications of this type of paraffin.

Introduction

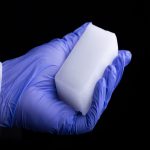

Colored solid paraffin is one of the most widely used types of paraffin in decorative and functional industries, which, due to its stable physical properties, high colorability, and easy moldability, is used in many fields including candle

production, decorative molds, and even cosmetics. This type of paraffin is essentially the same as regular solid paraffin, which becomes a beautiful, practical, and diverse product by adding permitted pigments and, in some cases,

fragrance.

Composition and Features of Colored Solid Paraffin

Colored solid paraffin is composed of paraffin wax with varying purity (usually between 1% to 5% oil) and color pigments. Some of its most important features include:

• High colorability

Solid paraffin is naturally white or transparent and has a very good ability to mix with mineral and organic pigments.

• Variable melting point (between 52 to 60 degrees Celsius)

This feature allows paraffin to have suitable moldability in production and molding processes.

• Odorless (unless fragrance is added)

Its odorless feature is important in the production of cosmetic products and scented candles.

• High color stability

The pigments used in paraffin are selected to be resistant to heat and light.

Production Method of Colored Solid Paraffin

The production of this product is carried out industrially and semi-industrially. The general production steps include:

-

Melting white solid paraffin

Base paraffin with the desired oil percentage (e.g., 3% or 5%) is melted in thermal boilers. -

Adding pigment

Special pigments for paraffin are added to the molten paraffin in powder or liquid form. These pigments must be permitted and resistant to high temperatures. -

Homogenization with an industrial mixer

The mixture must be stirred well so that the color is evenly distributed throughout the mass and no color layering or sedimentation occurs. -

Molding or packaging

The final product is poured into desired molds or prepared in block or sheet packaging.

In some cases, fragrances, glitter, or special additives are added to the mixture to give decorative or scented features to the paraffin.

Applications of Colored Solid Paraffin

The application of this type of paraffin is very diverse, but it can be categorized into three general groups:

-

Decorative candle making

The most important use of colored solid paraffin is in the production of colored candles. From simple tabletop candles to sculpted, scented, and decorative candles all use this material. -

Decorative and artistic industries

In art workshops, schools, and candle-making training centers, this material is used for teaching and producing decorative works. -

Cosmetic and hygienic products

In some products like lip wax, decorative soap, and certain topical creams, colored paraffin is used as a base, of course with adherence to health standards.

Color Variety and Effects

Colored solid paraffin can be produced in base colors like white, red, blue, green, yellow, orange, and purple, but it is also possible to mix colors and produce pastel or metallic shades.

In special cases, glitter, pearlescent, or metallic colors can be added to create special effects in decorative candles.

Important Points in Buying Colored Paraffin

For manufacturers and bulk buyers, the following items are very important:

• Oil Content: Paraffin with lower oil percentage (e.g., 1% to 3%) is more suitable for high-quality candles or hygienic products.

• Purity and quality of pigments: Colors must be permitted and resistant to heat and light.

• Melting point and viscosity: Should be chosen based on the type of application.

• Color stability: There should be no color change or fading when exposed to light and heat.

Difference Between Colored and Plain Paraffin

Plain paraffin is usually colorless and odorless and is mostly used in the production of white candles or industrial products. In contrast, colored paraffin has a decorative appearance and offers higher added value in artistic and

decorative applications. In terms of price, colored paraffin is more expensive due to additives.

Conclusion

Colored solid paraffin is an attractive and widely used product for candle makers, decorators, and hygienic industries. This material, with features like moldability, high colorability, thermal stability, and safety in use, has a special place

in the raw materials market of decorative industries. If you are looking for bulk purchase of this product, attention to oil percentage, pigment quality, and type of application will guarantee the final quality of your product.

If reliable supply, stable quality, and competitive pricing are important to you, Petroil brand with the slogan

“With us, superior power, victorious competition”