Do you know what edible solid paraffin is and how it is produced? This article discusses its production method as well as its uses and applications.

What is edible solid paraffin and how is it produced?

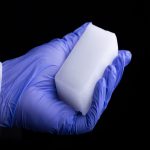

Edible solid paraffin is one of the by-products of crude oil refining, characterized by hygienic features and high purity, and used in various industries such as food packaging, fruit coating, gum production, and confectionery. This

colorless, odorless, tasteless substance with a specific melting point melts at human body temperature and is therefore used in some permitted edible applications. Structurally, edible paraffin consists mainly of long-chain saturated

hydrocarbons that have been refined under controlled conditions to remove harmful impurities such as sulfur, heavy metals, and aromatic compounds.

Edible solid paraffin production process:

Base oil extraction:

The process begins with refining crude oil and separating base oils. These oils contain paraffinic compounds.

Dewaxing process:

At this stage, wax is extracted from the base oil. The extracted substance is raw paraffin, which requires further refining.

Refining:

Raw paraffin is refined in several steps using acid treatment, filtration, and degassing to eliminate its chemical and physical impurities. At this stage, hygienic criteria and international food-grade standards such as FDA or EU Food

Grade are observed.

Bleaching and quality control:

To increase purity and remove remaining color, bleaching earths and specific filters are used. Then sampling and quality control tests are performed to ensure compliance with food-grade standards.

Conclusion:

Edible solid paraffin, thanks to a precise refining process, is a safe and practical substance in the food and packaging industries. In its production, compliance with global standards and industrial hygiene is of high importance.

Uses and Applications of Edible Solid Paraffin:

Due to its high purity, odorless and tasteless nature, and chemical stability, edible solid paraffin is used in various industries, mainly in indirect or limited contact with food. This compound is approved as an edible additive in many

countries and is produced and consumed under international health standards.

Below are the main applications of this type of paraffin:

-

Chewing gum production industry

One of the main uses of edible solid paraffin is in chewing gum production. It is used in the gum base as a softening and adhesive agent. Paraffin melts at mouth temperature and creates a uniform, smooth, and pleasant texture. -

Fruit and vegetable coating

In some countries, edible paraffin is used to coat the surface of fruits like apples, oranges, lemons, and cucumbers. This coating helps retain moisture, increase shelf life, prevent skin wrinkling, and improve appearance. It also acts as a barrier against microorganism penetration. -

Cheese coating

In the production of certain cheeses like cheddar, edible solid paraffin is used to coat the cheese surface. This coating prevents air and moisture contact and controls the ripening process, while also preventing mold growth. -

Chocolate and confectionery coating

Edible paraffin is used in some chocolate and confectionery products to enhance glossiness, prevent quick melting, and improve product appearance. It keeps the chocolate surface stable at room temperature and prevents sticking to hands or packaging. -

Anti-stick in food industry machinery

In some production lines, edible paraffin is used as a lubricant or anti-stick agent in molds and equipment. This facilitates production and prevents food products from sticking to molds.

Specifications of Edible Solid Paraffin:

Edible solid paraffin (Food Grade Paraffin Wax) must have specific physical, chemical, and hygienic properties to be considered safe and permitted for direct or indirect contact with food. These specifications are precisely defined by

international standards such as the U.S. FDA, European EC, or Codex Alimentarius.

Below are the key specifications of this type of paraffin:

-

High purity percentage

Edible paraffin must contain at least 99% saturated paraffinic hydrocarbons. This high purity ensures no harmful chemical impurities, heavy metals, or aromatic compounds remain. -

Melting Point:

Edible solid paraffin usually melts within the temperature range of 50 to 60°C. This temperature should allow it to become semi-liquid at body temperature for safe and harmless consumption. -

Color and appearance:

Edible paraffin must be colorless or clear white, odorless, and tasteless. Any coloring, odor, or taste indicates impurities or incomplete refining. -

Oil content:

The oil content in paraffin should be very low, usually less than 0.5%. Increased oil content reduces hardness and quality, possibly affecting food safety. -

Viscosity index:

The viscosity of edible paraffin must be within a controlled range to ensure optimal performance in coating, gum production, or packaging processes. -

Congealing Point:

The congealing point is usually close to the melting point and indicates physical stability and thermal behavior in production processes. -

Resistance to oxidation and decomposition:

Edible paraffin must resist thermal and chemical degradation. This prevents discoloration, unpleasant odors, or harmful by-products over time. -

Absence of heavy metals and toxic substances:

Edible paraffin must be free of harmful elements like lead, arsenic, mercury, or other heavy metals. Laboratory tests are conducted to confirm this.

How to purchase and obtain edible solid paraffin:

For producers in the food, confectionery, packaging, and agricultural export industries, sourcing high-quality edible solid paraffin that complies with international standards is key to maintaining product quality and customer

satisfaction. Therefore, selecting a reliable supplier with technical knowledge, strong supply network, and fast responsiveness is essential.

Steps to obtain edible paraffin from Petrovail:

-

Receive specialized consultation:

Petrovail experts are ready to recommend the most suitable food-grade paraffin based on application type, consumption amount, and production line conditions. This includes technical data, product specification sheet (TDS), and samples. -

Price and availability inquiry:

Considering global and domestic market fluctuations, Petrovail offers transparent and competitive conditions for updated pricing and delivery time. Access to diverse local and imported sources ensures consistent and fast supply. -

Official order registration:

After confirming conditions, a purchase contract or proforma invoice is issued. Petrovail offers official invoicing, nationwide shipping, and customized packaging. -

Fast and reliable delivery:

Utilizing a reliable transportation network and regional warehouses, Petrovail delivers orders to the desired destination in the shortest time possible. All shipments include lab reports, quality certificates, and secure packaging.

Why choose Petroil?

-

Direct sourcing from reliable domestic and international refineries

-

Continuous quality monitoring based on global standards

-

Competitive pricing with specialized after-sales services

-

Commitment to honesty, speed, and transparency in the supply process

For free consultation and to place an order for edible solid paraffin, contact Petroil experts.